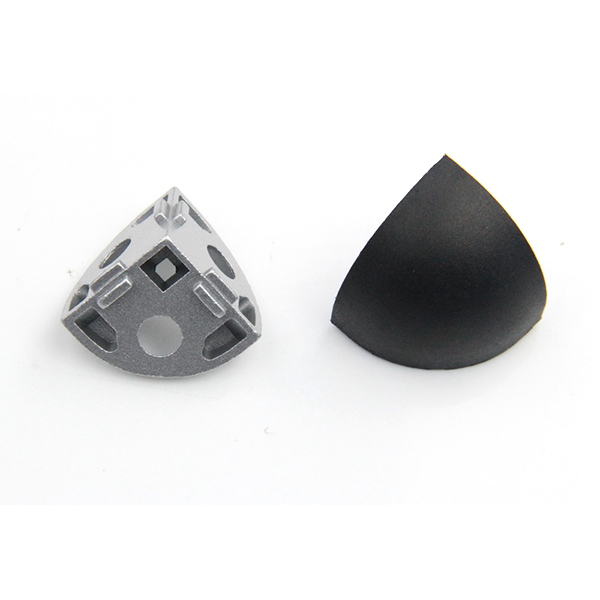

Plastic end caps are designed to fit snugly over the open ends of aluminum extrusions, providing a clean and polished appearance while protecting the extrusion from dust, dirt, and moisture. They are typically manufactured to match the specific dimensions of various aluminum profile series, ensuring a precise fit. These end caps can be either “proud” or “flush” with the surface of the extrusion, depending on the design requirements.

Material and Surface Treatment

Plastic end covers are commonly made from materials like polyamide (nylon) and are available in standard colors such as black and light gray. These materials offer durability and resistance to wear in industrial or commercial environments. The surface of the end caps is usually matte, providing a non-slip finish and a professional look.

Applications

Aluminum profile end caps find use in a variety of applications where aluminum extrusions are employed:

- Construction: They are used to finish off the ends of aluminum frames and structures, providing a neat and safe edge.

- Manufacturing: In machinery and equipment construction, end caps protect moving parts from debris and reduce the risk of injury.

- DIY Projects: They are used in home and hobby projects to give a professional finish to aluminum structures.

- Material Handling Equipment: End caps are essential for protecting the ends of aluminum profiles used in conveyors and other material handling systems.

Advantages

The use of frame end caps offers several benefits:

- Protection: They shield the ends of aluminum extrusions from environmental factors and potential damage.

- Aesthetics: End caps provide a finished look to aluminum profiles, enhancing the visual appeal of the structure.

- Safety: By covering exposed edges, end caps reduce the risk of injury in industrial settings.

- Easy Installation: Most end caps can be installed by hand or with a few taps from a soft mallet, saving time and avoiding the need for special tools.

Selection Criteria

When selecting the appropriate end cover for aluminum extrusions, consider the following:

- Compatibility: Ensure the end cap is designed for the specific aluminum profile series being used.

- Size and Shape: Choose the end cap that matches the size and shape of the profile’s end.

- Durability: Select a material that can withstand the environmental conditions the extrusion will be subjected to.