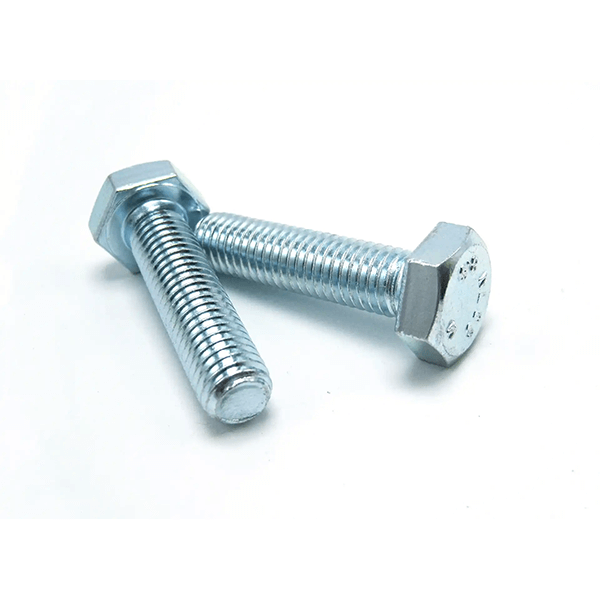

Hex bolts are distinguished by their six-sided hexagonal-shaped heads and threaded shafts. The hexagonal head provides multiple flat surfaces, making it easier to grip and manipulate using a wrench or socket tool during installation or removal. The shaft of a hex bolt is threaded, which means it has spiral grooves that allow it to screw into a compatible threaded hole or nut. The portion of the bolt between the head and the threaded section is known as the unthreaded shank, which adds structural integrity to the bolt and prevents it from being threaded all the way through a component。

Material and Durability

Hex bolts are commonly manufactured from high-strength materials such as carbon steel, alloy steel, or stainless steel. This ensures durability, corrosion resistance, and the ability to withstand significant mechanical stress. For applications exposed to harsh or corrosive environments, stainless steel options are often preferred due to their superior resistance to rust and chemicals

Advantages

Compact and Space-Saving: The design allows these bolts to be used in tight spaces where other fasteners may not fit.

High Torque Capacity: The hex socket design enables the application of high torque, ensuring a secure and stable connection.

Aesthetically Pleasing Finish: The flush surface after installation gives a sleek and clean appearance, making it suitable for visible applications.

Versatile: Used in various industries, including automotive, construction, machinery, and furniture.

Common Applications

Hex bolts are widely utilized in machinery assembly, automotive parts, heavy equipment, and precision instruments. Their ability to deliver high clamping forces makes them indispensable for applications requiring reliable and strong joints. They are also used in environments where vibration resistance is crucial, such as engines and mechanical assemblies.

Types of Hex Bolts

Hex bolts can be categorized based on threading, head and shaft size, and materials:

- Fully Threaded Hex Bolts: These have threading that spans the entire length of the shaft.

- Partially Threaded Hex Bolts: These have threading that covers only a portion of the shaft, leaving an unthreaded shank below the head.

- Standard Hex Bolts: These have a relatively smaller head size compared to heavy hex bolts.

- Heavy Hex Bolts: These have a larger head size and a thicker shank compared to standard hex bolts.

Material Options

Hex bolts are manufactured using a variety of materials to suit different applications and environments:

- Carbon Steel Hex Bolts: Widely used due to their affordability and general-purpose characteristics.

- Stainless Steel Hex Bolts: Popular for their excellent corrosion resistance.

- Alloy Steel Hex Bolts: Enhanced mechanical properties, used in applications requiring high tensile strength.

- Brass, Bronze, and Titanium Hex Bolts: Offer specific benefits such as corrosion resistance and high strength.

- Galvanized Steel Hex Bolts: Have a zinc coating that provides protection against corrosion.

- Aluminum and Plastic Hex Bolts: Used where weight reduction and resistance to corrosion are priorities.

Installation

Hex bolts are installed using tools such as a hex bolt wrench, spanners, hex keys, socket sets, ratchet spanners, etc. The hexagonal head provides enough grip from various angles for the tool operator, which eases the installation and removal process. They can be used either in pre-tapped holes or along with nuts, and the torque applied to the bolt determines the level of tightness achieved in the connection.